How our (Dutch) chlorella is grown

- By Geertje (Gre) Haak

- 14 Mar 2022

The chlorella from our own brands (Plantforce and Big Food) is grown in the Netherlands. Our chlorella pyrenoidosa (sorokiniana) as a raw material reduces the environmental impact because no agricultural land is used. The transport lines are short and therefore there is a reduced emission of CO2 and particulate matter. This fits perfectly with Plent's vision

Three types of chlorella production methods

There are roughly three possible methods of producing - or culturing - chlorella: heterotrophic, mixotrophic and autotrophic. Our own brands of chlorella (Plantforce and Big Food) use the heterotrophic production method in closed stainless steel tanks.

Heterotrophic

chlorella production

This production method usually takes place in a bioreactor, as with our own chlorella brands (Plantforce and Big Food). The algae are grown in a sterile environment so that the algae are not exposed to contaminants. In addition, the quality is not adversely affected by differences in the amount of sunlight present, as is the case with autotrophic and mixotrophic production.

Mixotrophic

chlorella production

This production method takes place in tubes or flat-screen systems. A good example is the glass pipe system from Algomed in which the chlorella is cultivated in glass tubes. This prevents the algae from coming into contact with contaminants. A disadvantage is that the degree of presence of sunlight influences the quality of the chlorella and is therefore not completely controllable.

Autotrophic

chlorella production

This production method usually takes place in open ponds. The chlorella is grown in ponds. A potential drawback is that the algae can be exposed to contaminants. Moreover, the quality is difficult to control because no influence can be exerted on the sunlight present.

The production process of our Dutch Chlorella

Heterotrophic production of chlorella involves 6 different steps. The first step - and most important for good quality chlorella - is cleaning the microalgae. The result of going through the entire production process is a chlorella tablet of the highest quality.

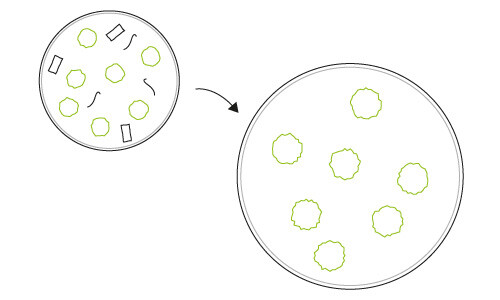

Step 1

Cleaning of microalgae

In the first step of the production process, the microalgae are released from bacteria.

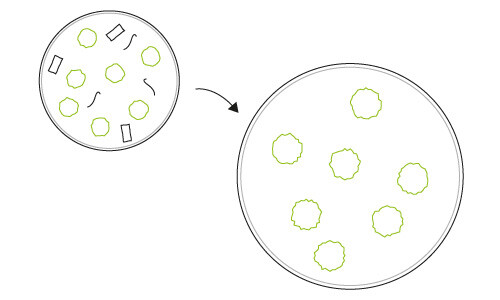

Step 2

Algae in the nursery

In the 'nursery' the first algae are produced from the microalgae to start the production process.

Step 3

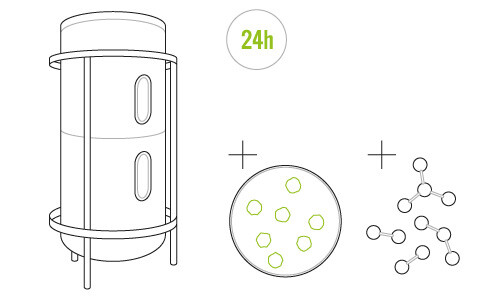

Algae divide in the fermenter

In the fermenter, the algae divide, creating a multitude of algae.

Step 4

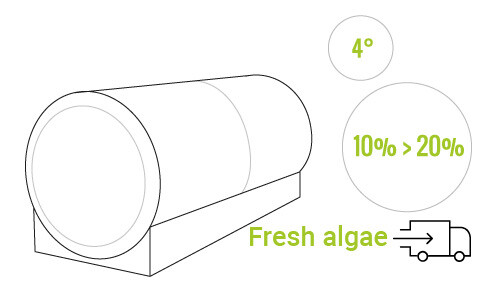

Algae in the cooling tank

The algae pass into the cooling tank where an extra variant can be made by centrifuging.

Step 5

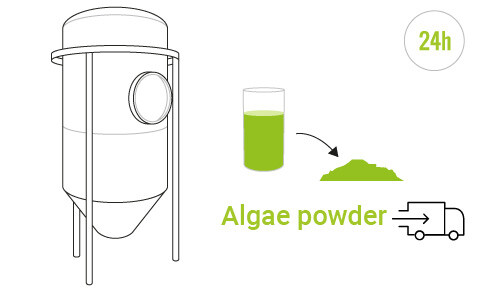

Spray drying of the algae

The algae are converted into powder in the spray dryer.

Step 6

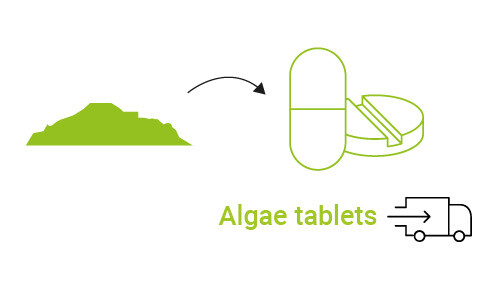

Making tablets

The powder is used to make tablets.

Properties of heterotrophic chlorella production

The production of chlorella in a heterotrophic way differs from other methods:

- The 1st step of photosynthesis is skipped

- Sugar is used as an energy source

- The chlorella is grown in a sterile bioreactor

- There is complete control over the cultivation process and the quality of the chlorella

- It is a sustainable production method

Advantages of heterotrophic production of chlorella

Top quality

The chlorella pyrenoidosa from our own brands (Plantforce and Big Food) is grown in a sterile environment and is therefore 100% pure. Because the chlorella is cultivated in a closed tank (bioreactor), no external contamination is possible. The chlorella does not contain heavy metals or residues of pesticides. In addition, there is no influence of sunlight or changeable weather conditions. Pure Dutch water is used during cultivation. Due to the cultivation method, the nutritional profile can be fully influenced for consistent quality.

Sustainable

First of all, algae are very durable as a product. Algae are an excellent replacement for animal products. In addition, the heterotrophic cultivation method is a very sustainable way of algae cultivation with a low surface area use, no agricultural land is used. Production takes place in the Netherlands, which means that the transport lines are short and therefore less CO2 and particulate matter is emitted.

Mild taste

Due to the cultivation method, the chlorella pyrenoidosa (sorokiniana) of our own brands (Plantforce and Big Food) has a pleasant mild (nut / grass-like) taste. Our chlorella is easy to mix with other flavors. This is an advantage because chlorella does not have a good reputation when it comes to flavor. Our chlorella can be easily mixed with other flavors due to its mild taste.

Other benefits

- Produced in the Netherlands

- Meets EU quality criteria

- Cleanest chlorella production possible

- Free from contaminants

- Free from harmful and foreign substances

- Consistent quality and nutritional value

- Full control over the cultivation process